A quality manufacturing operation needs water that is purer than what comes out of local tap systems. This is especially true if the water comes from a nearby source, such as a river or lake. However, many manufacturing plants don’t meet these high water purity standards. This means their water contains many microorganisms and contaminants that are detrimental to the manufacturing process.

Furthermore, water is a limited resource. According to the U.S. Census Bureau, the manufacturing industry alone uses 18 billion gallons of water daily. This statistic highlights the need for manufacturers to find sustainable water solutions to conserve this precious resource.

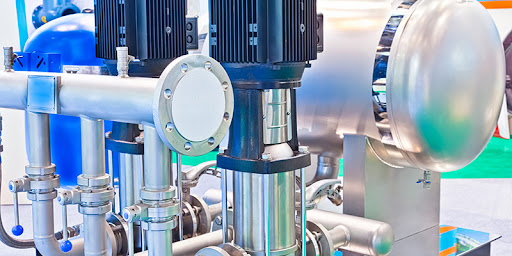

Through a high-performance industrial water treatment solution, manufacturing firms can meet their clean and reusable water needs. This investment comes with several benefits that can’t be overlooked.

Maintaining Quality Products

Firms that manufacture consumables like food, beverages, cosmetics, and skincare products need 100% clean water to maintain the quality of their products. Any impurities can cause their goods to fail disinfection and purification requirements, which are usually stringent. Manufacturers can ensure that their products pass quality inspections with flying colors by treating the water.

Furthermore, contaminants can compromise the integrity of the final product. This can, for example, reduce its shelf-life, leading to high customer dissatisfaction. And unhappy customers can drain a company’s revenue, considering that 91% of customers won’t be doing repeat business and will likely tell 9-15 others (maybe more) of the bad experience.

Saving Money

Revenue is important for any business, and keeping costs down is a good way to maximize returns. One major factor that drives up expenses is waste, and many manufacturing processes use large volumes of water and discard them afterward. By treating the water, manufacturers can use it, again and again, to reduce their water bill while ensuring an efficient operation.

The treated water is also safe for human consumption, and it is something that employees can drink while on the job. Manufacturers can even sell it, creating an additional revenue stream.

Another way that water treatment saves manufacturers money is that it prevents equipment damage. Some equipment needs water for various processes, including cooling and lubrication, and unclean water can be detrimental to its operation. Not only does this mean that manufacturing needs to pay thousands for repairs or replacements, but it can also cause injuries if the machine happens to malfunction while someone is using it.

Protecting Environment

Manufacturing companies that don’t care about reducing their environmental footprint risk scaring off investors and customers. If the water released from the manufacturing process contains chemicals and other contaminants, it can be harmful to the environment. By treating the water, manufacturers are helping protect the planet – the only one they have to do business on. Furthermore, these firms can avoid fees and fines that would likely incur if, for instance, they deposited unclean water into the sewer system.

Conclusion

The industrial water treatment system manufacturers invest in will depend on the type of operation. However, it is a solid investment that helps them maintain product quality, cut costs and help protect the environment. These benefits will ensure that the manufacturing firm remains competitive in a hyper-competitive marketplace.

Contact Culligan Industrial Water – your source for top-quality industrial water treatment systems.