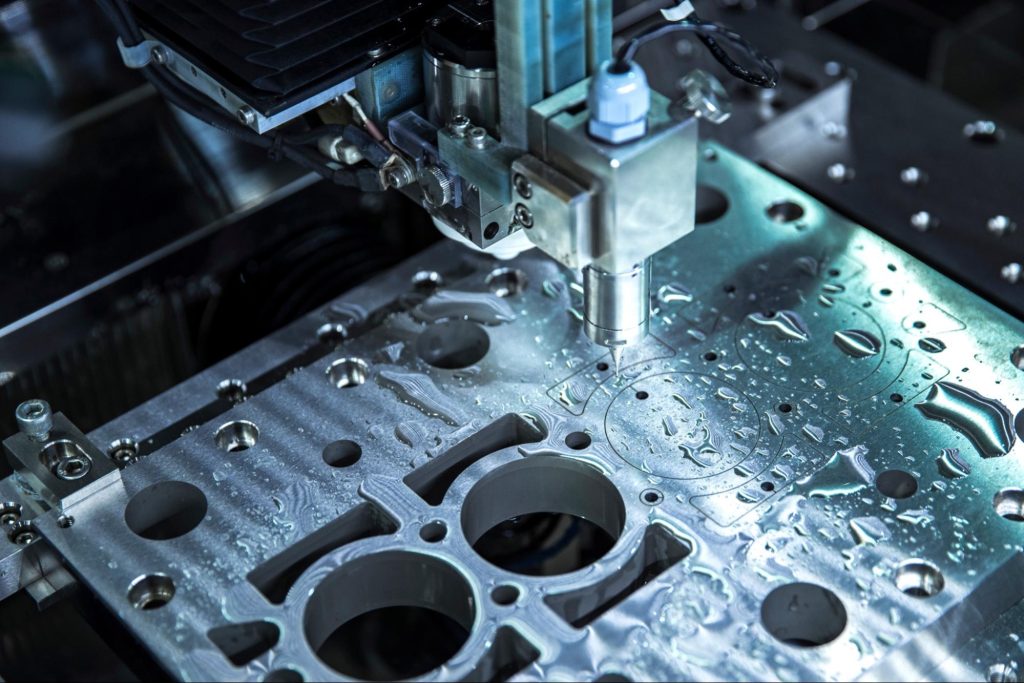

A good manager must remember that one should not operate with a large amount of merchandise in stock and should not occupy a larger space than necessary nor be stored for a long time. Therefore, purchases of raw materials such as Tungsten Tube Metals must be based on production history and current stock. So far, we have seen that properly managing your raw material stock results in numerous benefits for your industry. However, some mistakes can significantly harm your management. We decided to list the most common mistakes in raw material management so you don’t make them and keep your management up to date.

Not Working With Minimum Stock

The minimum stock, or safety stock, is the minimum amount you need to have in the company of a particular product. It is intended to cover the supplier’s replacement delays and guarantees the manufacture of its products. It is essential to keep the minimum stock of items in stock, so if you need to produce an extra quantity, you don’t have to make last-minute purchases, which usually have a higher cost.

Buy More Than Necessary

We’ve all heard that inventory is money, haven’t we? Well, with that sentence, you can understand the importance of studying the market and buying the necessary raw materials. The buyer must have at hand, at the time of purchase, reports that accurately inform which goods are the most sold and the sales forecast for the coming months. Thus, it is possible to make purchases of raw materials more efficiently.

Manage Your Industry Manually

One of the biggest mistakes managers makes is to believe in manual management and keeping notebooks and spreadsheets filled without automation, which can lead to errors and rework. By doing this, labor that could be used for production becomes involved in tasks that can be automated. By understanding how important inventory management is, it is easy to see that its implementation is not as difficult as it seems and will only bring good results in the overall functioning of your business.

We also saw the mistakes many managers make that could be avoided with a reliable investment in software. Now that you understand the importance of raw material inventory management by tungco, you don’t want to be a manager who keeps wasting time and money on processes that could be optimized, right? A management system in your industry is essential, as it can draw your attention when the raw material level is low, which can harm your production flow. In addition, the software can help when making purchases, pointing out the best time and ideal quantities.