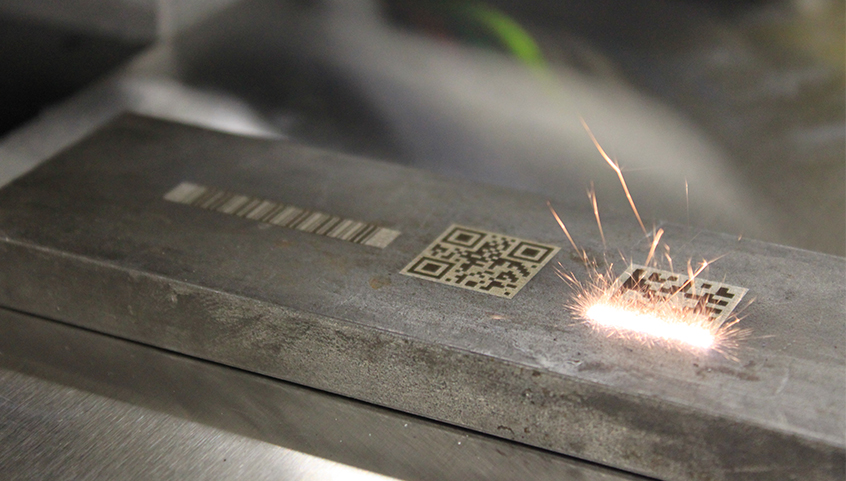

It is possible to engrave barcodes, serial numbers, and logos on metal using CO2 or fiber lasers.

A fiber laser is an excellent tool for marking industrial products because of its long operating life and low maintenance requirements. It is still possible to get crisp marks with these lasers despite compromised parts integrity.

Prior to CO2 laser engraving, the metal must be coated with a protective coating (or pasted with a protective coating). Marking agents are applied to metal with CO2 lasers to temporarily mark it. In addition to wood, acrylic, stone, and other materials, CO2 lasers can etch through a variety of materials.

Almost every Windows program is compatible with Epilog laser systems.

Types of lasers

There are several things to keep in mind when using lasers and materials of different types.

In addition to CO2 lasers, marking agents can also be coated or pretreated to mark metal. A fast-acting marking agent must also adhere quickly to metal and be low-pressure. When lasering pieces that can be cleaned afterward, it is best to increase the power.

CO2 lasers maintain tolerance and strength as well as not removing material. Metals such as anodized aluminum and painted brass do not require pretreatment before they are painted or anodized.

Metal can be engraved with fiber lasers using fiber lasers. Materials such as aluminum, nickel-plated metals, and stainless steel can be marked with laser fibers.

It is possible for a laser beam generated by the device to mark some materials, however. The beam can pass through transparent material to engrave an engraving table. In the case of organic materials, such as wood, clear glass, and leather, fiber laser systems may not be the best choice.

Mark types

It is possible to determine which Lasit laser marking on metal option will be used based on the type of metal being marked. Engraving is produced by vaporizing the surface of an object with a laser. As beams are often shaped like cones, marks are often shaped like cones. It is possible to create deep engravings under harsh conditions when repeated operations are performed.

In most cases, ablation exposes a material’s lower layer by removing its top layer. It is possible to ablate powdered metals or anodized metals.

By heating an object’s surface, it is possible to mark it. A high contrast is produced as a result of the annealing process, which results in oxides being formed on metals. Raised surfaces are the result of trapped gas bubbles in a material during cooling. Melted materials form foam when they melt. It is possible to change the color of a metal surface quickly by polishing it. Mirror-like reflections will appear on your metal surface. It is used to anodize metals such as steel alloys, iron, titanium, and other metals that contain carbon or oxide. Plastic is most commonly used to mark stainless steel, but foam can also be used. The best polish should be used on matte finishes.

Taking into account the following information

The speed, power, frequency, and focus of the laser can also be altered besides annealing, etching, and polishing stainless steel. In general, fiber lasers are brighter than CO2 lasers on anodized aluminum. Gray shades of light are engraved on aluminum by fiber lasers instead of black lasers. In addition to deep etching, aluminum can also be oxidized or colored.

In the process of marking titanium, lasers emit different colors. Even so, they can be adjusted based on the color of the room.

Marks made of three different colors of anodized aluminum

Different marking effects can be produced by removing certain colors and materials from aluminum. Lasers are capable of removing anodized layers partially or completely.

To make aluminum scratch-resistant, ceramic coatings (5-30 mm thick) are applied. Decorative effects can be achieved with colored porous layers. There are a number of techniques and materials that can influence the results when using different laser wavelengths.

How do laser marking and engraving differ?

Their similarities are overshadowed by very important differences. Aside from how each technology looks, it also differs in its penetration depth.

In some cases, lasers are actually used to remove materials by engraving or etching them. There is no use of a laser, which can only mark surfaces. There is a crucial difference between laser engraving and laser etching that needs to be understood.

Traceable laser markings

Permanent laser marking is one of the advantages of laser marking machines. A cost-effective option compared to other methods is to mark at the beginning of production.

The markings on your products will still be high-quality, regardless of the coating or shot blasting you use. The serial number as well as the barcode will not be damaged.

No consumables are available

It is more efficient to mark with chemicals and ink free since consumables are not needed.

Labeling with lasers

Lasers alter surfaces slightly when they interact with them.

Using low-power beams, high-contrast marks can be created without damaging material when they are slowly moved across it.

- In the process of oxidizing materials, the laser produces their black spectra when they are heated.

- During annealing, metal surfaces are heated to a low temperature.

- It does not damage the surface during the process.

In separating laser markings from laser engravings, several factors should be considered.

- It is not available in every place, but it is available in some.

- By charring or annealing plastics and metals with a laser, they can be colored or darkened.

- Lasers can mark any of these items, including those that have been annealed, migrated, foamed, and colored.

- Aside from plastic and metal, medical device parts can also be made of stainless steel or metal alloys.

- The laser markers also can mark logos, UIDs, QR codes, and bar codes in addition to bar codes.