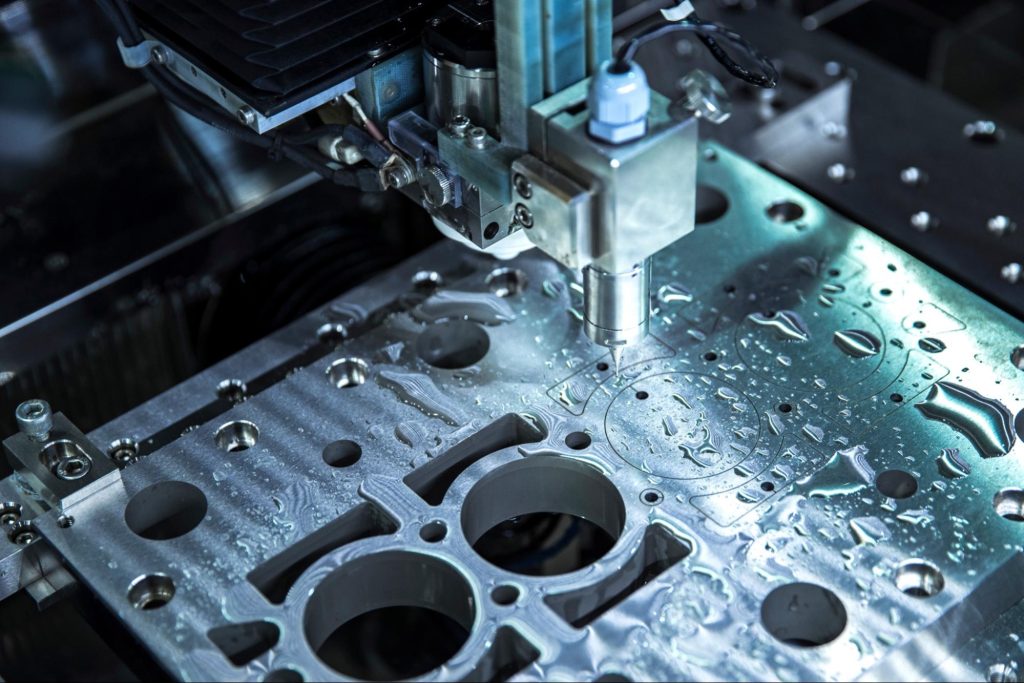

High-quality milling machine components need extensive setup and adjustment. Even little inaccuracies might lead to disastrous results. A dependable and efficient workholding system is required to make excellent components. Custom workholding systems are critical for production milling because they give the flexibility and variety needed to generate an infinite number of component shapes and sizes.

It is possible to obtain substantially greater tolerances and make components with significantly superior finishes by adjusting the workpiece holds and clamps to meet the unique geometry of the item. Furthermore, specialized workholding arrangements are frequently faster and more efficient than generic fixtures. Learn more about the benefits of unique workholding solutions in the sections below.

Greater Tolerances

Workpieces can be modified to fit the component and held in place more securely using a bespoke configuration. As a result, there will be less movement and vibration, resulting in increased precision.

Furthermore, unique workholding configurations frequently allow for greater chip evacuation. This is due to the fixtures’ ability to be constructed with particular channels and grooves that direct chips away from the cutting region. It reduces tool wear and breakage while also improving surface smoothness.

Improved Finishes

Custom workholding can enhance accuracy and chip evacuation, resulting in higher surface finishes. Furthermore, bespoke fixtures frequently allow for more aggressive machining. They can be built with a greater number of cutting edges, resulting in quicker material removal.

Enhanced Efficiency

Increased efficiency is another advantage of specialized workholding. It is possible to modify the orientation of the part using a custom setup without having to remove it from the fixture. As a result, numerous sides may be machined in a single configuration, resulting in shorter total cycle times. Furthermore, unique fixtures frequently make it simpler to access difficult-to-reach sections of the component, which helps to boost productivity and minimize the chance of mistakes.

Increased Security

Custom-made components are held more firmly, reducing the chance of their being dislodged and dropped during the milling process. This contributes to improved worker safety and lowers the chance of accidents.

Furthermore, unique workholding configurations frequently allow for an improved view of the cutting operation, aiding in operator awareness and lowering the possibility of accidents. Custom fittings can assist limit the risk of accidents by decreasing the need for operators to reach the cutting area.

Available Workholding Services on Demand

PAWS Workholding provides different types of custom workholding. They have more than 60 years of combined workholding expertise developing and producing unique fixtures to match your exact requirements.

They provide entire fixture and programming packages with full CAD capabilities, which means they can help you with the engineering needs for printing your parts, as well as design and build your fixtures, pick the right equipment, program the component, and install it on your workstation.

Among their other advantages are the following:

- Their whole product line is designed and manufactured in the United States.

- They are able to deal with short lead periods and provide speedy turnaround.

- They provide cycle time analysis as well as process optimization evaluations.

- In addition, they offer engineering consultancy and collaborative design services.

Maintain Your Competitive Advantage

To be competitive, you need unique workholding solutions if your firm relies on precise milling processes. Working with a bespoke workholding specialist allows you to take advantage of cutting-edge technology while keeping your company functioning at optimal efficiency.

Contact PAWS Workholding now for more information on bespoke workholding or to obtain a quotation. You’ll be fully satisfied when you work with us.