This guide is about ultrasonic welding and the benefits that it brings to a whole host of manufacturing processes and specialist industries. It is a process where components of all shapes and sizes are welded together in the most robust and precise way, for use within a wide range of industries.

What is ultrasonic welding?

It is a common process where moulded plastic parts are welded together for use within a wide range of components and industries. Using bolts and solder, or adhesives, is not as effective as is required by the best manufacturers, where there is a need for strict and long-lasting materials and components. These traditional processes can also leave visible joints and a messy aesthetic, whereas ultrasonic welding gives a strong joint in a seamless way.

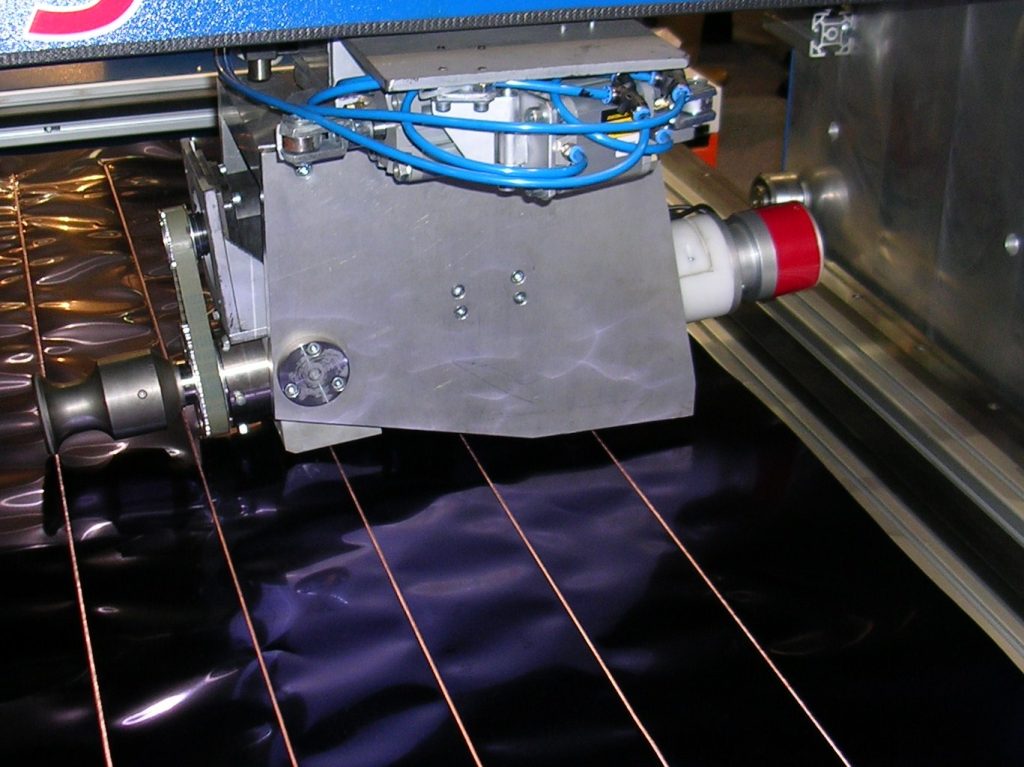

Ultrasonic welding is a technique where ultrasonic vibration is used to bring two parts together, welding them to create one whole piece. This is an alternative to two parts being joined together using heat. Instead, the energy from the vibration causes a solid-state weld. This makes it a process that is highly sought after within myriad industries.

Where do you see ultrasonic welding being used?

Ultrasonic welding is used within a wide range of applications and industries. This is due to the impeccable finish that it provides a completed piece. An example of this is within the mattress manufacture trade, where contract bedding that is used for hospital, care home, and hotel use requires a sturdier finished mattress that will have the ability to withstand constant use, as well as face spillages of liquids and bodily fluids without damaging the integrity of the mattress. Traditional mattress manufacturing where there are visible seams would not last as long as a mattress manufactured using the ultrasonic welding process.

You also see ultrasonic welding used as a formidable manufacturing process in industries such as the electronics industry, the medical industry, for the creation of consumer products, packaging and manufacturing, for components in the automotive industry and for aerospace and the military.

What are the advantages of ultrasonic welding?

Ultrasonic welding can be an effective method of manufacturing for an incredibly wide range of materials. This is one of the main reasons it has become such a popular and commonly used process across a whole host of the abovementioned industries. It provides precision, at speed, which helps to improve and increase the speed at which a manufacturing process and run of components and materials can be manufactured. It is also an incredibly safe process when it is directly compared with some other welding techniques. There is little chance of the process leading to damage of the surrounding material and equipment, providing great reliability and flexibility.

Ultrasonic welding is used within various industries and myriad applications, as we have seen above. Choosing to partner with a manufacturer and supplier of goods that utilises the many benefits of ultrasonic welding will give you access to a finished product that is cost-effective, robust, and long-lasting, the perfect addition to your project.